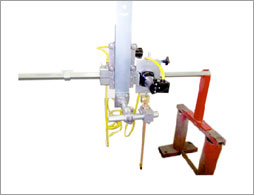

| FILWEL SMARTWELDER is one of the sleekest and most versatile AUTOMATIC WELDING & SURFACING SYSTEMS in the world. It offers various overlay options without compromising precision. The best feature of the FILWEL SMARTWELDER system is that it offers various options for mounting the welding head and the wire feeder. The welding head can be mounted by keeping the beam stationary and allowing the carriage to move or by keeping the carriage stationary and allowing the beam to move. This makes the FILWEL SMARTWELDER ideal for a variety of welding and surfacing applications and makes it unique. |

|

|

| Other features and options of the system are |

|

|

| |

Extremely lightweight, easily portable |

|

|

|

| |

Easy to assemble and dismantle |

|

|

|

| |

Wire feeder mounting options |

|

|

|

| |

Can weld with a range of wire sizes |

|

|

|

| |

Operator-friendly |

|

|

|

| |

Easy to maintain |

|

|

|

| |

Hand-held Pendant option |

|

|

|

| |

Customized options available |

|

|

|

| |

Submerged arc welding attachment |

|

|

|

| |

Flux recovery unit for submerged arc welding |

|

|

|

| |

Fume extraction system for welding head |

|

|

|

| |

Chiller for cooling welding torch |

|

|

|

|

| |

| Optional attachments are available for gas-shielded welding & submerged arc welding. |

| SMARTWELDER D Series |

| Ideally suited for welding of steel mill rolls, in-situ or in-shop welding of cement mill rolls and tables. |

|

|

|

|

|

| VERSATILE AND RELIABLE AUTOMATIC WELDING AND SURFACING SYSTEMS FOR REBUILDING: |

|

|

|

Flat and Cylindrical Surfaces |

|

|

Steel Mill Rolls |

| |

|

Cement & Coal Pulverizer Rolls & Tables |

| |

|

Wear Plate Manufacture |

| |

|

Sugar Mill Rolls |

|

|

|

|

|

Profiles & Patterns |

|

Internal Cladding of Pipes |

|

Screwflights |

|

|

|

|

|

|

|

| SMARTWELDER S Series |

|

|

Single axis system for shop fabrication and repairs |

| |

|

Linear or stepping option |

| |

|

Longer beam length option |

| |

|

Wire feeder mounting option |

| |

|

Standard and cantilever torch mounting |

|

|

|

|

|

| SMARTWELDER D Series |

|

|

Twin-axis system for shop and site fabrication and repairs |

| |

|

Options of standard and cantilever arrangements |

| |

|

Longer beam length option |

| |

|

Welding of grinding mill rolls and tables at site |

| |

|

High and low profile wire feed set up |

|

|

|

|

| Standard Arrangement |

|

Standard Arrangement |

|

|

|

| |

|

|

| Cantilever Arrangement |

|

Cantilever Arrangement |

|

|

|

|

|

|

|

|

| Please Consult for Customized Equipment |

| Cladding systems for

other applications |

|

Automatic Welding & Surfacing Systems

refurbishing steel mill rolls |

|

|

|

|

| |

| Optional Extras |

|

|

Submerged Arc Welding Attachment |

| |

|

Flux Recovery Unit For Submerged Arc Welding |

| |

|

Fume Extraction For Welding Head |

| |

|

Chiller For Cooling Welding Torch |

|

|

|

|

| |

|

| A Large Range of Industrial Build-Up & Hardfacing Cored Wires are Available for use with the above Equipment. |

|

| |